hfrr friction test|rtec hfrr specs : convenience store The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance . RESULTADOS POR LOCALIDADE (Estado ou Banca) Rio d.

{plog:ftitle_list}

web潍坊 硕辰机械 设备www.813.net. www.813.net-新萄京官网 是一家专业从事水泥包装机械和干粉砂浆成套设备设计、制造和销售服务的制造企业。. www.813.net厂拥有一批优秀的工程技术骨干,在水泥包装机械领域积累了丰富的生产经验。. 依靠自身的专业技术优势,结合 .

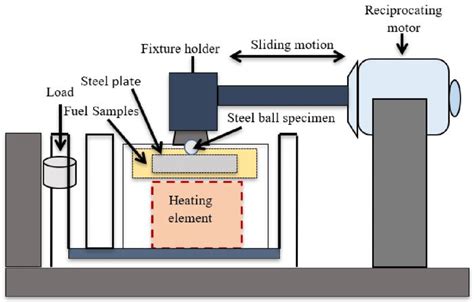

Research confirms HFRR is the best test to accurately measure diesel fuel lubricity. Continued advances in vehicle hardware and the increased use of more complex fuels, mean it is important to check that industry tests can still identify .A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. The HFRR is a ball-on-plate instrument used .

rtec hfrr specs

Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing machine contains programmable force control (no .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance .A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. specified . With over 2000 systems worldwide, .Reciprocating friction testers such as Plint Tribology Products’ TE77 High Frequency Friction Machine 15 and PCS Instruments’ HFR2 High Frequency Reciprocating Rig16 are useful for .

The Petrolytical HFRR system has proven effective in addressing the lubricity of diesel fuels using an electromagnetic motor to provide low amplitude oscillation of a moving specimen pressed against a stationary specimen.

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants.HFRR is a reciprocating friction and wear test system which is going under microprocessor control. It provides a fast and repeatable assessment of the performance of fuels and has .This next generation High Frequency Reciprocating Rig HFRR test module has real-time programmable force control, piezo sensors to measure real time friction, in-line total wear scar depth, wide temperature range, and voice coil actuators. .Such test rigs are sometimes referred to as a high-frequency reciprocating rig (HFRR) or SRV-type test. (SRV is an acronym for the German expression Schwingung Reibung Verschleiß, which meansreciprocating friction and .

The HFRR test was developed over 20 years ago and has stood up to all of the changes made to fuels and engines since its development. Increased use of biofuel, reduction of sulphur and continuous changes within .Friction and Wear Testing 2 Testing on SRV and HFRR • Both are high frequency reciprocating rigs • Both are test rigs wit a ball-on-disc configuration • SRV (schwingung, reibung, verschleis) main test rig we use for research • SRV we investigate testing techniques and methods; different temperatures, varying frequencies and operating loads.

Fast and repeatable testing The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels andThis next generation High Frequency Reciprocating Rig HFRR test module has real-time programmable force control, piezo sensors to measure real time friction, in-line total wear scar depth, wide temperature range, and voice coil actuators. The tester is mostly used to evaluate diesel fuel lubricity. The ease of use, programmable down force .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of

HFRR A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. specified . HFRR Overview Test Area Schematic: With over 2000 systems worldwide, the PCS HFRR is . Within the area of the point of contact of the ball and plate in the HFRR method friction node, emerging oxide layers with higher ionic potential may contribute to a reduction in the friction coefficient and, consequently, to a lesser wear scar on the test ball. In addition, in the HFRR method, the friction node is constantly surrounded by the .Friction and wear results of engine oil tested using ballon-flat testing with the TriboLab HFRR setup under ASTM D6425-17 conditions (350 N, 50 Hz, 1 mm, 120°C, 2 h). Left: Calculated COF using the 10% top points on stroke, with inset showing the high-resolution data of the friction force at ~3600 s. The PCS HFRR is the industry leading instrument for analysing diesel fuel lubricity. PCS are the original manufacturers of the HFRR instrument and are the only instrument supplier specified on the following test methods: ISO 12156, ASTM D6079, ASTM D7688. . Maximum Friction Force: Dependent on amplitude maximum 10.0 N; Temperature: Ambient to .

The HFRR Test is a speedy and screening technique for evaluation of friction in terms of co-efficient of friction and wear profiles for fuels and lubricants under the dry and lubrication conditions. This method generates an absolute value of wear scar for diesel fuels and for lubricants it provides a plan of performance before the lubricant is . The objective of this work was to understand the flexibility of the HFRR test by investigating the impact of increased test severity on wear. The main variable investigated was the effect of load, which was varied from 2-10N. . Certain fuels exhibit unusual friction coefficient behaviour, with temporary periods of significantly elevated .A test method that is popular for extreme pressure and coefficient of friction & wear determination is the SRV test instrument. This test analyzes the lubrication between a lubricant and two specimens, where the top specimen oscillates over the bottom specimen in either a linear or rotational fashion. One test methodWear due to excessive friction resulting in shortened life of engine components, such as diesel fuel injection pumps and injectors, has sometimes been ascribed to lack of lubricity in the fuel. . (HFRR) — Part 1: Test method. This standard has been withdrawn. Follow. Table of contents. Foreword. Introduction. 1 Scope. 2 Normative references .

HFRR A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. specified . HFRR Overview Test Area Schematic: With over 2000 systems worldwide, the PCS HFRR is .

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of engine oils, greases and other . The HFRR test is critical in assessing how different formulations, including biodiesel blends, affect fuel lubricity and engine performance [2]. The Shift to Low-Sulphur Diesel and Its Consequences . . The decrease in lubricity led to higher friction between moving parts, accelerating the wear and potentially shortening the lifespan of these .

Rtec Instrument offers several solutions for engine related tests to measure friction, wear, adhesion, roughness, fretting, and more. Study piston ring liner friction and wear at engine speed on a lab scale. Test engine additives with our HFRR and SRV test setup. Study DLC and other coating adhesion using our scratch test setup. This new document differs from ISO 12156-1:2018 as it specifies a test method for assessing the lubricating property of fuels used in diesel engines, with or without lubricity enhancing additives and with HFRR wear scar diameters of 350 μm to 700 μm, using the high-frequency reciprocating rig (HFRR), but now also used in concert with a digital camera (seen .

rtec hfrr

High Frequency Reciprocating test HFRR (ASTM D6079, ASTM D7688, ISO 12156-1, CEC F-06-A-96, BS EN 590, JPI-5S-50-98 and IP 450/2000) is a standard . Friction is measured real time using high frequency pie-zo sensors. 7KH WHPSHUDWXUH .The term lubricity is often defined as the ability of a fluid to minimize the degree of friction and/or damage between surfaces in relative motion under load conditions, in this case, diesel fuel [1,2]. . Recent advancements in equipment using HFRR to test for the lubricity of diesel have shown to improve results and data that can help avoid .HFRR test instrument: Sample quantity: 20 ml: Unit: Diameter of a wear dome in µm: Analysis for: diesel fuel: Brief description: This instrument is a vibration friction wear tester. The HFRR value (high frequency reciprotating rig) is determined by pressing a 6 mm steel ball onto a steel plate with a defined hardness and surface roughness with .

The Petrolytical HFRR High Frequency Reciprocating Rig is based on devices that have been used for many years in the area of tribology (friction and lubrication). Typically used to determine the lubricity of a samples during slow cycling sliding. The Petrolytical HFRR system has proven effective in addressing the lubricity of dieselHFRR The standard test determines extreme pressure, friction wear properties of greases, solid bonded films, gear/hydraulic fluids, and lubricant oils. All tests are done in . This test assess friction and wear parameters of self-lubricated materials in .

This document specifies a test method using the high-frequency reciprocating rig (HFRR) with a digital camera, for assessing the lubricating property of petroleum-based middle distillate fuels, paraffinic diesel fuels, and biodiesel blends, with or without lubricity enhancing additives, and with HFRR wear scar diameters (WSDs) of 350 ?m to 700 ?m.Test procedure. The HFRR High Frequency Reciprocating Rig (HFRR Reciprocating Rig) is based on devices that have been used for many years in the Tribology (Friction and Lubrication) Department of the Faculty of Engineering at Imperial College London.. Systems of this type are used to determine the lubricity of a sample during slow cyclic sliding. The HFRR system has .This next-generation HFRR testing machine uses programmable force control (no dead weights). Its unique flexure based design, rigid platform, in-line friction monitoring at high frequencies, and fully automated test programs allows for high repeatability and precision measurements. Down Force The applied force is measured

test for ankle ligament tear

high frequency friction tester

Resultado da MAV aufs Smartphone × Hier bekommen junge Leute alle Infos zu den Ausbildungsberufen der Metall- und Elektro-Industrie, freie Ausbildungsstellen und Bewerbungstipps direkt aufs Smartphone.

hfrr friction test|rtec hfrr specs